MARINE

& OFFSHORE

MARINE & OFFSHORE

Through 3D laser scanning, survey tasks required for the inspection, installation, retrofit, conversion, and maintenance of offshore installations and ships can be performed rapidly and, most importantly, with unparalleled accuracy. Since no two offshore installations or ships are identical, 3D laser scanning offers a highly effective solution for creating as-built models, including registered point clouds, 3D mesh models, 3D CAD models, BIM models, and plant design models.

Compared to traditional survey methods, which are often slow and limited in both the amount and quality of data they can capture, 3D laser scanning delivers fast results with unparalleled precision, generating billions of individual 3D data points with millimeter or even micron accuracy. Using 3D laser scan data, we can perform other as-built services, including, but not limited to, machinery alignment and inspection, creation of 2D CAD technical documentation, and deformation and wear analysis. The unmatched accuracy and efficiency of 3D laser scanning ensure maximum reliability in offshore and maritime operations, while also minimizing downtime and preventing costly errors.

AS-BUILT SERVICES

As-Built Survey for Retrofit & Conversion

Registered Point Clouds

3D Mesh Models (Scan to Mesh)

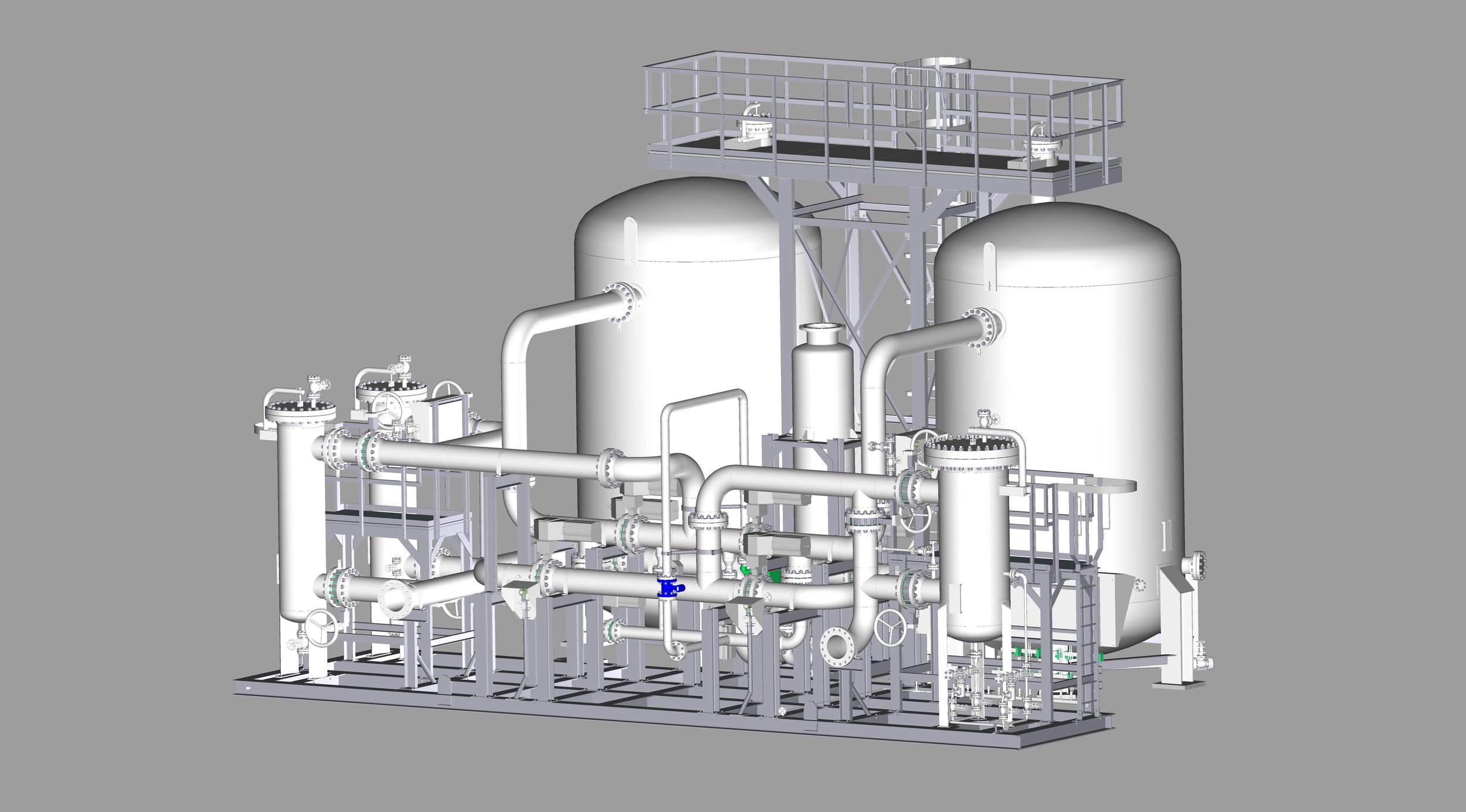

2D & 3D CAD Models (Scan to CAD)

BIM Models (Scan to BIM) & Plant Design Models (Scan to Plant)

Machinery Alignment & Inspection

Storage Tank Inspection & Calibration

Volume Surveys

Construction Verification

Deformation & Wear Analysis

VR/AR & 3D Digital Content

XRF & Thickness Analysis

APPLICATIONS

Digital Twin

Offshore Installations & Platforms

Marine Vessels/Ships

Seawall & Coastal Facilities

PRODUCTS

SCAN TO CAD

POINT CLOUD

CAD MODEL