ENGINEERING

& ENERGY

TUNNELING

& ARCHITECTURE

OFFSHORE

Where We Excel

Industries We 3D Laser Scan & Measure Using Laser Trackers

REVERSE

ENGINEERING

Rebuild complex components as accurate as-built 2D & 3D CAD models from 3D laser scan data.

INDUSTRY

& ENERGY

Accurately document complex industrial facilities in 3D to streamline engineering operations.

MINING &

TUNNELING

Model mining and tunneling operations in 3D to coordinate layouts, expansions, and critical infrastructure.

CIVIL ENGINEERING

& ARCHITECTURE

Create precise as-built 2D & 3D documentation to support accurate planning, design, and construction.

MARINE &

OFFSHORE

Produce accurate 2D & 3D as-built models of vessels and offshore assets for critical engineering processes.

ABOUT US

When Accuracy Matters

PT SURYA KWON SUNG (PT SKS) is a leading service provider in 3D laser scanning, laser tracker measurement, dimensional inspection, and as-built 3D modeling in Indonesia. Above all else, we prioritize measurement precision and efficiency by leveraging the latest equipment and a comprehensive software suite. Experience unparalleled accuracy in every dimension with us.

WE ARE A HEXAGON DISTRIBUTOR

Elevate manufacturing precision, productivity, and quality with PT SURYA KWON SUNG—your authorised Hexagon Manufacturing Intelligence partner in Indonesia.

Exceptionally Accurate

Our As-Built Products

When accuracy is non-negotiable, we perform machinery alignment and inspection using laser tracker CMMs, measuring arm CMMs, and metrology-grade handheld 3D laser scanners.

For clients who prefer to handle post-processing in-house, we deliver clean, registered point clouds in color or black & white—ready for modeling, measurement, and analysis.

Scan to Mesh: From 3D laser scan data, we create clean, detailed 3D mesh models in a range of 3D mesh formats—ideal for visualization, reverse engineering, and digital archiving.

Scan to CAD: Using 3D laser scan data, we reverse engineer accurate as-built 3D CAD models—capturing complex geometry for redesigns, part replication, tooling, and component fit-up.

Scan to BIM: As-built BIM models are developed from 3D laser scan data, providing a true-to-field 3D model of current conditions for engineering, coordination, and construction.

Scan to Plant: Detailed plant design models and piping isometric drawings are produced from 3D laser scan data to support retrofit work, layout validation, and engineering deliverables.

Using 3D laser scanning, we generate accurate tank inspection and calibration reports for aboveground and underground storage tanks, supporting compliance, verification, and documentation.

For fast, high-accuracy volume measurements, we perform volumetric surveys with 3D laser scanning—ideal for storage tanks, ship ballast & fuel tanks, and material stockpiles.

Clear as-built 2D CAD documentation is created to match your standards—including engineering, architectural, and inspection drawings tailored to your project requirements.

By comparing design models to point clouds (or point clouds to each other), we deliver clash detection and deviation checks that reduce rework and confirm field conditions.

To quantify deformation and wear, we create high-resolution 3D color maps using 3D laser scanning and/or CMM measurements—making changes easy to visualize and report.

Utilizing 3D laser scanning, we generate accurate 2D & 3D topographic models. Additionally, with GNSS RTK rovers, we georeference your project data to real-world coordinates.

Ground penetrating radar (GPR) provides underground mapping in both 2D and 3D, helping identify subsurface features and utilities with clear, usable results.

With 3D laser scanning and TrueProp software, we deliver fast, accurate propeller inspections in accordance with ISO 484 tolerance standards—supporting repairs and verification.

By leveraging 3D laser scanning, real-world objects and environments become high-quality digital 3D models—ideal for VR, AR, simulation, visualization, and 3D digital content creation.

We use handheld LIBS and XRF analyzers to accurately identify materials, including carbon content for steel grade identification, and ultrasonic thickness gauges to precisely measure thickness.

Authorised Hexagon Distributor

Shop Hexagon Equipment

Portable Measuring Arms

Portable probing & 3D laser scanning for small-to-medium sized parts.

Laser Tracker Systems

Portable probing & 3D laser scanning for medium-to-ultra large sized parts.

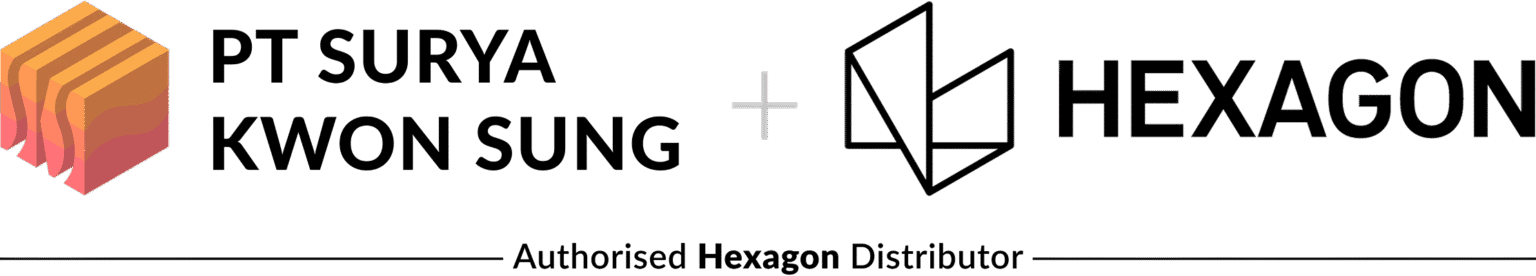

Coordinate Measuring Machines (CMMs)

Fixed ultra-high accuracy probing & 3D scanning for small-to-large sized parts.

Handheld 3D Laser Scanners

Portable and flexible 3D laser scanning for small-to-medium sized parts.

Structured Light Scanners

Portable high accuracy 3D laser scanning for small-to-medium sized parts.

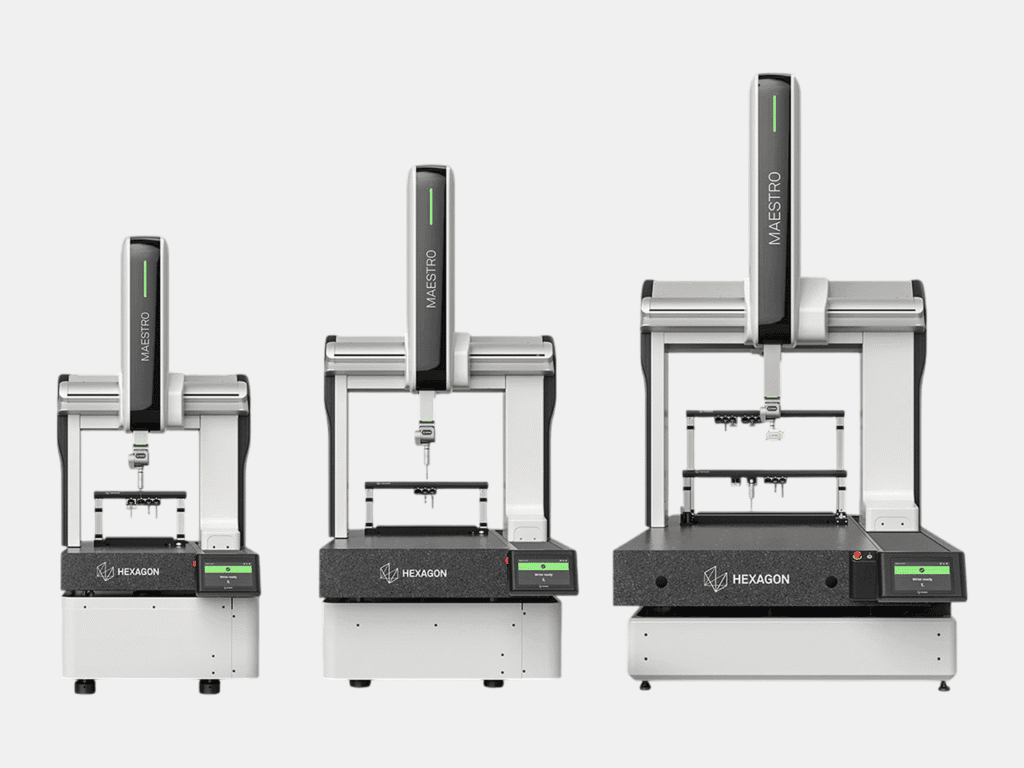

Metrology Software

Comprehensive suite of metrology software including for reverse engineering, inspection, and design.

As-Built Modeling

Scan to CAD - From Accurate Point Cloud to Precise 3D CAD Models

OURCLIENTS

We have partnered with clients across a diverse range of industries including petrochemical, defense, mining, manufacturing, and civil engineering.

OUR CLIENTS

We have partnered with clients across a diverse range of industries including petrochemical, defense, mining, manufacturing, and civil engineering.

Exceptionally Accurate

Learn More About

Unrivaled Efficiency

What is Terrestrial 3D Laser Scanning

Terrestrial 3D laser scanning is an advanced reality-capture method for surveying medium to large assets with speed and accuracy. A tripod-mounted 3D laser scanner captures millions to billions of accurate 3D points—each with X, Y, and Z coordinates—to form a highly detailed point cloud of the environment. This point cloud becomes a reliable foundation for accurate as-built 2D drawings and 3D CAD models, inspection and analysis, visualization, and high-fidelity digital twins.

01

Accuracy

Millimeter accuracy for reliable measurements of medium to large assets.

02

Speed & Coverage

Capture millions of points per second for fast, comprehensive documentation.

03

Cost Savings

Reduce rework, change orders, and repeat site visits with complete, data-rich capture.

04

Safety

Capture from up to 130 m away, keeping personnel clear of hazards.

Unmatched Flexibility

What is Handheld 3D Laser Scanning

Handheld 3D laser scanning is a portable, high-detail measurement method that uses a high-accuracy 3D laser scanner to capture the exact shape of small to medium sized objects. By moving the 3D laser scanner around the part, it records dense 3D data and generates an accurate digital model for inspection and reverse engineering. With accuracy of up to 0.02 mm, handheld scanning is ideal for complex geometry, tight spaces, and components that require fine detail.

01

Accuracy

Up to 0.02 mm accuracy for accurate measurement of small to medium objects.

02

High Detail

Captures fine features and complex geometry for inspection and reverse engineering.

03

Speed

Fast capture with minimal setup—ideal for rapid inspection and short turnaround projects.

04

Flexibility

3D Scan in tight spaces and on-site conditions where tripod setups are impossible or slow.

Unparalleled Accuracy

What is Laser Tracker Measurement

Laser tracker measurement is a metrology-grade solution for high-accuracy probing, alignment, and dimensional inspection—ranging from small parts to large assemblies. A laser tracker CMM measures 3D coordinates in real time by tracking a reflector or probe, making it ideal for critical tolerance checks, installation alignment, tooling verification, and quality control. With probing accuracy of up to 0.015 mm, it delivers confidence for the most demanding measurement tasks.

01

Accuracy

Probing accuracy up to 0.015 mm for critical inspection of small to large objects.

02

Large-Scale Capability

Measure small to large objects and assemblies while maintaining high accuracy.

03

Real-Time Alignment

Instant feedback for faster alignment, assembly guidance, and corrective adjustments.

04

Traceable QA/QC

Clear measurement results and reporting to support quality documentation and compliance.

Industry Leading