CONSTRUCTION

VERIFICATION

CONSTRUCTION VERIFICATION

By comparing an existing design model to a point cloud captured through 3D laser scanning—or by directly comparing two distinct point clouds—our advanced clash detection analysis pinpoints potential conflicts with equipment, structural elements, or environmental features. Detecting these issues early in the design phase prevents on-site complications, minimizes construction delays, and reduces the costs associated with rework or material waste.

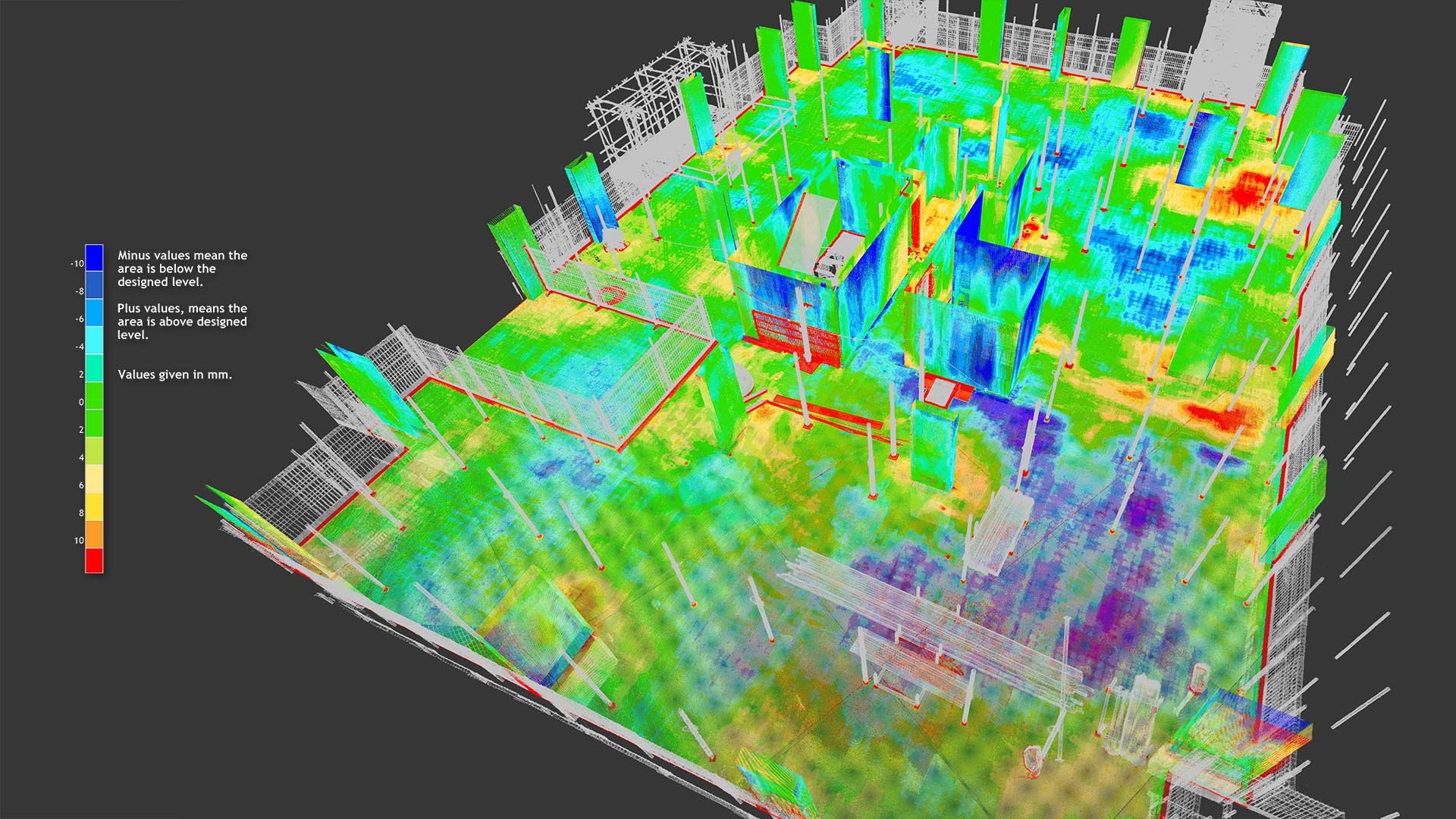

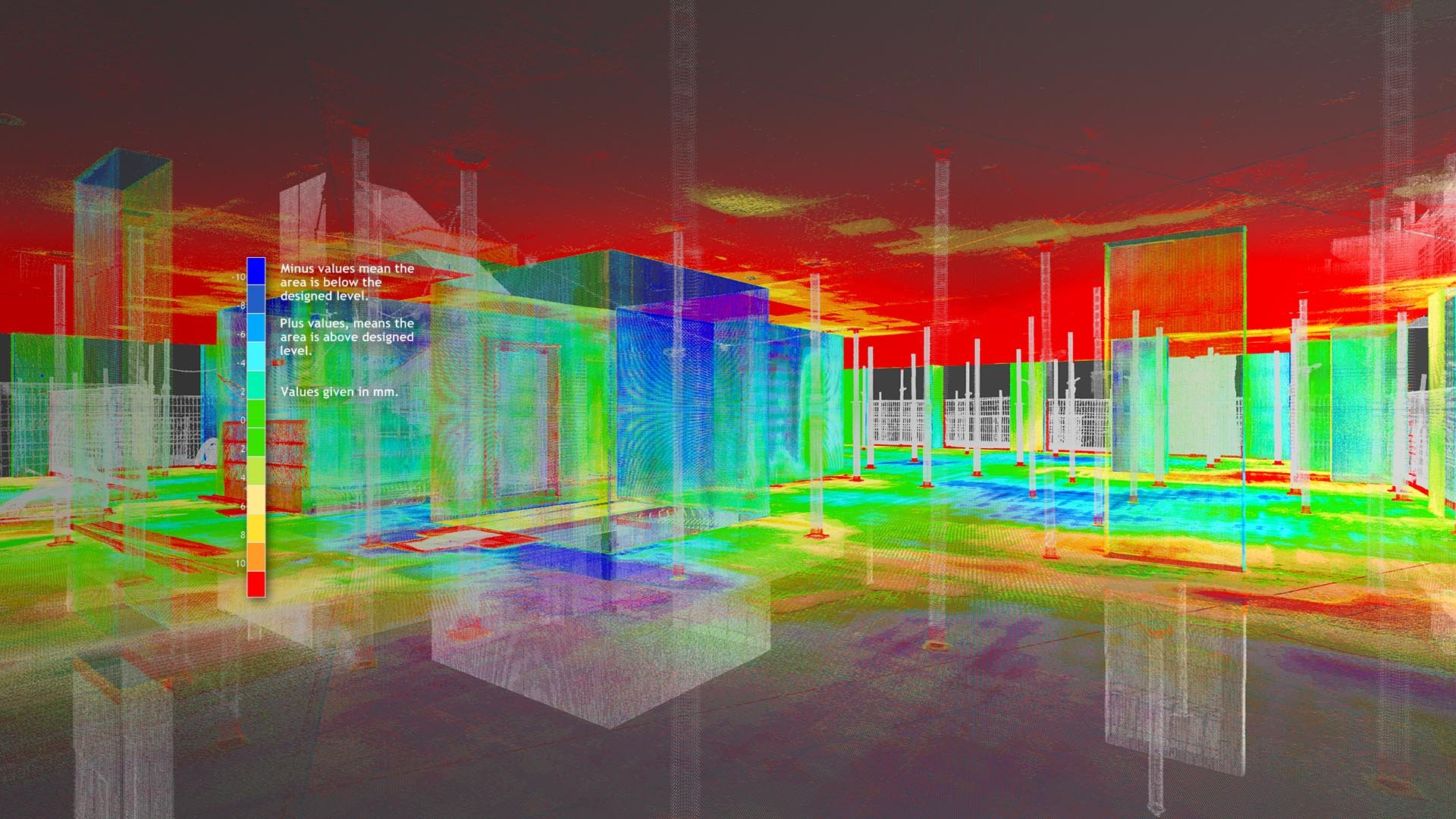

In construction verification, our 3D laser scanning-based services are pivotal in ensuring that as-built conditions precisely match the original design intent. By generating detailed 2D and 3D deviation/deformation color maps, we accurately identify discrepancies between the design model and the constructed environment. These maps are created by comparing 3D laser scanned point cloud data with the original BIM or CAD model or by analyzing differences between sequential 3D laser scans. Regular scanning at critical project milestones allows teams to monitor progress, swiftly address emerging issues, and uphold rigorous quality control standards. Additionally, this data integrates seamlessly with BIM platforms, ensuring that the design model reflects precise as-built conditions.

Complementing these core capabilities, our services include a comprehensive range of specialized inspections. We offer cross-sectional analysis, surface levelness and flatness assessments, slope analysis, tunnel inspection, volume surveys, as well as checks for alignment, verticality, roundness, perpendicularity, and parallelism. This extensive suite of services underscores our ability to execute every project and inspection with unmatched accuracy.

EQUIPMENT USED

Terrestrial 3D Laser Scanner: Leica RTC360 (3D Accuracy: 1.9 mm)

Terrestrial 3D Laser scanner: Faro Focus S 150 (3D Accuracy: 2 mm)

Terrestrial 3D Laser Scanner: Leica BLK360 (3D Accuracy: 4 mm)

Metrology-Grade Handheld 3D Scanner: Shining FreeScan UE Pro (3D Accuracy: 0.02 mm)

Laser Tracker CMM: Faro Vantage S6 Max (Accuracy: 0.016 mm + 0.0008 mm/m)

Measuring Arm CMM: Faro Quantum Max (3D Accuracy: 0.030 mm)

Total Station: Leica FlexLine TS10 1” R1000 (Accuracy: 1 mm, Angular Accuracy: 1 s)

RTK GNSS: Leica GS18 T GNSS RTK Rover (Accuracy: 8 mm)

GPR: Radiodetection LMX200

Ultrasonic Thickness Gauge: Olympus 38DL PLUS (Accuracy: 0.001 mm)

Sphere Targets

APPLICATIONS

Clash Detection Analysis of Structures and Equipment

2D & 3D Deviation/Deformation Color Map Of Structures and Equipment

Cross-Sectional Analysis, Surface Levelness and Flatness Assessments, Slope Analysis, Tunnel inspection, and Volume Surveys

BIM Models (Scan to BIM) & Plant Design Models (Scan to Plant)

Machinery Alignment & Inspection

2D CAD Documentation

Deformation & Wear Analysis

Dimensional Check: Alignment, Verticality, Roundness, Perpendicularity, and Parallelism

GPR (Underground Mapping)

Georeferencing

Thickness Analysis