REVERSE ENGINEERING

INDUSTRIAL SURVEYS

MINING APPLICATIONS

CIVIL ENGINEERING

OFFSHORE SURVEYS

APPLICATIONS OF 3D LASER SCANNING

-

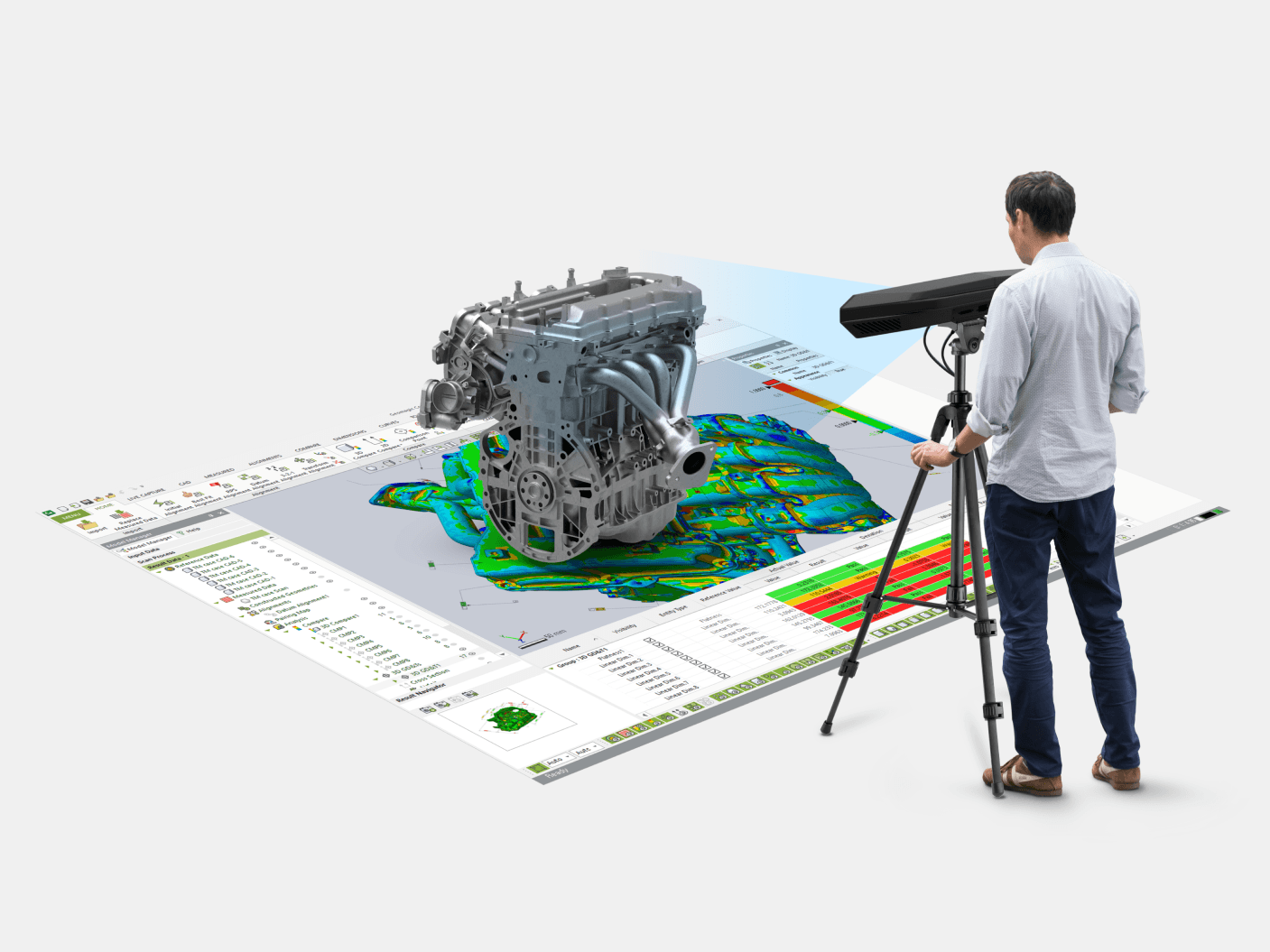

REVERSE ENGINEERING

Streamline the creation and inspection of specialized parts and equipment through reverse engineering, where 3D laser scanning and CMM measurements are used to create highly accurate as-built 2D and 3D CAD models. Whether for production, inspection, or documentation, we tailor our reverse engineering workflow to achieve the greatest measurement accuracy by leveraging the latest equipment and software.

-

INDUSTRY & ENERGY

Elevate industry operations with 3D laser scanning, which rapidly collects spatial 3D data and minimizes on-site disruptions. From aiding in digital twin modeling and machinery alignment and inspection to storage tank inspection and calibration, volume surveys, and registered point cloud generation, our precise as-built deliverables support 2D and 3D CAD models, BIM models, 3D mesh models, and plant design models—optimizing design, installation, and maintenance processes.

-

MINING & TUNNELING

Optimize safety and efficiency in mines and tunnels with 3D laser scanning. Our advanced workflows and equipment accurately map underground and aboveground environments, detect structural issues, and reduce costly disruptions. From registered point clouds and plant design models to 2D and 3D CAD models, BIM models, and 3D mesh models, we offer a comprehensive range of as-built services.

-

CIVIL ENGINEERING & ARCHITECTURE

Advance civil and architectural projects with faster, more accurate surveying through 3D laser scanning. From digital twin models, BIM models, 2D and 3D CAD models, and floor plans to topographic data, deformation and wear analysis, and construction verification, our workflows deliver reliable as-built documentation that enhances design fidelity and streamlines construction, inspection, and maintenance operations.

-

MARINE & OFFSHORE

Transform offshore and maritime operations with advanced 3D laser scanning solutions. Whether for inspection and installation or retrofit and maintenance, our high-precision workflows create accurate as-built deliverables—including registered point clouds, 2D and 3D CAD models, BIM models, and plant design models. By utilizing 3D laser scanning, we streamline digital twin modeling, machinery alignment and inspection, and deformation and wear analysis.

ABOUT US

When accuracy matters

PT SURYA KWON SUNG (PT SKS) is a leading service provider in 3D laser scanning, dimensional inspection, and as-built 3D modeling in Indonesia. Above all else, we prioritize measurement precision and efficiency by leveraging the latest equipment and a comprehensive software suite. Experience unparalleled accuracy in every dimension with us.

WE ARE A HEXAGON DISTRIBUTOR

Elevate manufacturing precision, productivity, and quality with PT SURYA KWON SUNG—your authorised Hexagon Manufacturing Intelligence partner in Indonesia.

OUR AS-BUILT PRODUCTS

-

REGISTERED POINT CLOUDS

For clients who prefer to do their own post point cloud data processing, we offer registered colored or black & white point clouds.

-

3D MESH MODELS

Scan to Mesh: We provide a wide range of as-built point cloud to 3D mesh model conversions in various mesh model file formats.

-

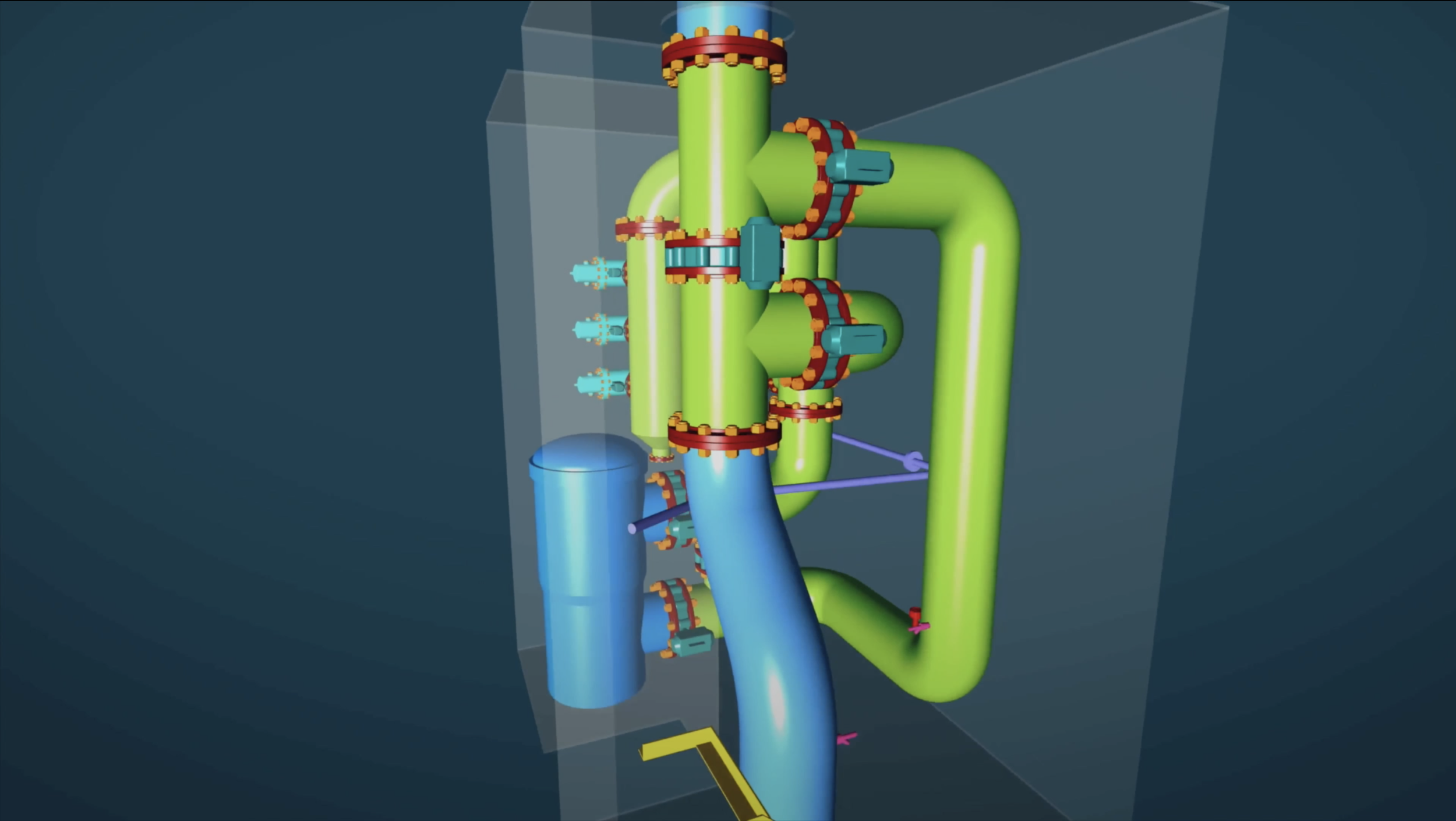

3D CAD MODELS

Scan to CAD: We offer highly accurate as-built point cloud to 3D CAD model conversions in multiple formats.

-

BIM MODELS

Scan to BIM: We deliver a variety of as-built point cloud to BIM (Building Information Modeling) model conversions.

-

PLANT DESIGN MODELS

Scan to Plant: We provide as-built point cloud conversions into detailed plant design models and piping isometric drawings.

-

LASER TRACKER ALIGNMENT & INSPECTION

For machinery alignment and inspection, where accuracy is critical, we utilize laser tracker CMMs, measuring arm CMMs, and metrology-grade handheld 3D laser scanners.

-

STORAGE TANK INSPECTION & CALIBRATION

Using 3D laser scanning, we create accurate storage tank inspection and calibration reports for both aboveground and underground storage tanks.

-

VOLUME SURVEYS

With 3D laser scanning, we perform highly accurate and efficient volumetric surveys, often employed in storage tanks, ship ballast & fuel tanks, and stockpiles.

-

2D CAD DOCUMENTATION

We offer a variety of as-built 2D CAD documentations including but not limited to engineering, architectural, and inspection drawings.

-

CONSTRUCTION VERIFICATION

By comparing design models to point clouds or point clouds to each other we provide clash detection analysis and construction verification.

-

DEFORMATION & WEAR ANALYSIS

Using 3D laser scanning and/or CMM measurements, we create 3D color map models for deformation and wear analysis.

-

TOPOGRAPHIC MAPPING & GEOREFERENCING

Utilizing 3D laser scanning, we generate 2D & 3D topographic models. Additionally, with GNSS RTK rovers we georeference point clouds, BIM & plant design models, and GPR data.

-

GPR (UNDERGROUND MAPPING)

Our ground penetrating radar (GPR) enables us to provide underground mapping services to produce both 2D & 3D data.

-

PROPELLER INSPECTION

3D laser scanning with TrueProp Software allows for highly fast and accurate propeller inspections following ISO 484 tolerance standards.

-

VR/AR & 3D DIGITAL CONTENT

By employing 3D laser scanning, we convert real-world objects and environments into digital 3D models for applications such as virtual reality (VR), augmented reality (AR), & 3D digital content.

-

XRF & ULTRASONIC THICKNESS ANALYSIS

For reverse engineering, we use XRF analyzers to accurately determine the type and specifications of materials, and ultrasonic thickness gauges to precisely measure thickness.

SHOP HEXAGON

-

PORTABLE MEASURING ARMS

Portable probing & 3D laser scanning for small-to-medium sized parts.

-

LASER TRACKER SYSTEMS

Portable probing & 3D scanning for medium-to-ultra large sized parts.

-

COORDINATE MEASURING MACHINES (CMMS)

Fixed ultra-high accuracy probing & 3D scanning for small-to-large sized parts.

-

HANDHELD 3D LASER SCANNERS

Portable and flexible 3D laser scanning for small-to-medium sized parts.

-

STRUCTURED LIGHT SCANNERS

Portable high accuracy 3D laser scanning for small-to-medium sized parts.

-

METROLOGY SOFTWARE

Comprehensive suite of metrology software including for reverse engineering, inspection, and design.

SCAN TO CAD

OUR CLIENTS

We have partnered with clients across a diverse range of industries including petrochemical, defense, mining, manufacturing, and civil engineering.

WHAT IS 3D LASER SCANNING

3D laser scanning is a cutting-edge survey technique that surpasses the capabilities of traditional survey methods. By capturing millions to billions of precise individual 3D data points, each with its own X, Y, and Z coordinate, 3D laser scanning produces a highly detailed point cloud of any environment. This point cloud enables a broad range of applications, including the creation of digital twins, 3D mesh models, 3D CAD models, BIM models, plant design models, machinery alignment & inspection, storage tank inspection & calibration, volume surveys, 2D CAD documentation, construction verification, deformation & wear analysis, topographic mapping, georeferencing, and VR/AR & 3D digital content.

Safety & Cost

3D laser scanners collect up to 2 million data points per second. Coupled with advanced HDR imaging, they can deliver colorized 3D point clouds with millimeter or even micron accuracy, ensuring a highly detailed digital conversion of any object or environment.Accuracy & Efficiency

With measurement capabilities ranging up to 150 meters and the use of a low-energy laser, 3D laser scanners can safely operate in hazardous environments. Their pinpoint accuracy also provides significant cost advantages by reducing rework and errors, as well as streamlining inspection, installation, and maintenance operations.