REVERSE ENGINEERING

INDUSTRIAL SURVEYS

MINING APPLICATIONS

CIVIL ENGINEERING

OFFSHORE SURVEYS

APPLICATIONS FOR 3D LASER SCANNING

-

Reverse Engineering

Reverse engineering is the most efficient and effective method to create accurate digital conversions of scanned features and elements. In reverse engineering, a 3D CAD model is created from a point cloud, which is obtained from 3D scanning and CMM measurements. Reverse engineering is commonly used in industry to create digital twins and 3D models of physical objects and to produce 2D documentation.

-

INDUSTRY & ENERGY

3D laser scanning allows for quick and accurate equipment inspection/maintenance, verification of secondary containment, tank calibration, scientific measurement, and 3D visualization/surveying to reduce and mitigate costly shutdowns. Common industry and energy applications include digital twin, oil & gas, chemical plants, and power plants.

-

Mining & Tunneling

Using 3D laser scanning the condition of the mine or tunnel can be recorded with accurate measurements capable of recording any signs of failure. Other applications of 3D laser scanning include calculating stockpile volumes, inspection/maintenance of equipment, creation of digital twins, and asset and facility management.

-

Civil Engineering & Architecture

We offer a range of surveys for civil and architectural development. 3D laser scanning allows for the fast and accurate production of architectural documentation including floor plans, BIM (Building Information Modeling), elevation, 3D CAD models, and 2D or 3D topographical surveys. Common applications include digital twins, buildings, bridges, roads, and power lines.

-

MARINE & OFFSHORE

Marine applications of 3D laser scanning include offshore installations (oil rigs) and vessels. Through 3D laser scanning, survey tasks required for retrofit, conversion, and maintenance of a vessel or offshore installation can be performed efficiently and accurately allowing for the creation of other data including digital twins. Other services can also be performed including the calibration of ballast and fuel tanks.

ABOUT US

Your experts in 3D scanning.

PT. Surya Kwon Sung is a leading company in as-built 3D laser scanning and modeling in Indonesia. Above all else we prioritize measurement precision and efficiency by leveraging the newest equipment and a comprehensive software suite. Experience unparalleled accuracy in every dimension with us.

OUR As-BUILT PRODUCTS

-

Registered Point Cloud

For clients who would like to do their own post-production operations we offer registered point clouds.

-

3D Mesh Models

Scan to Mesh: We offer a array of as-built point cloud to 3D mesh model conversions in any mesh model file type.

-

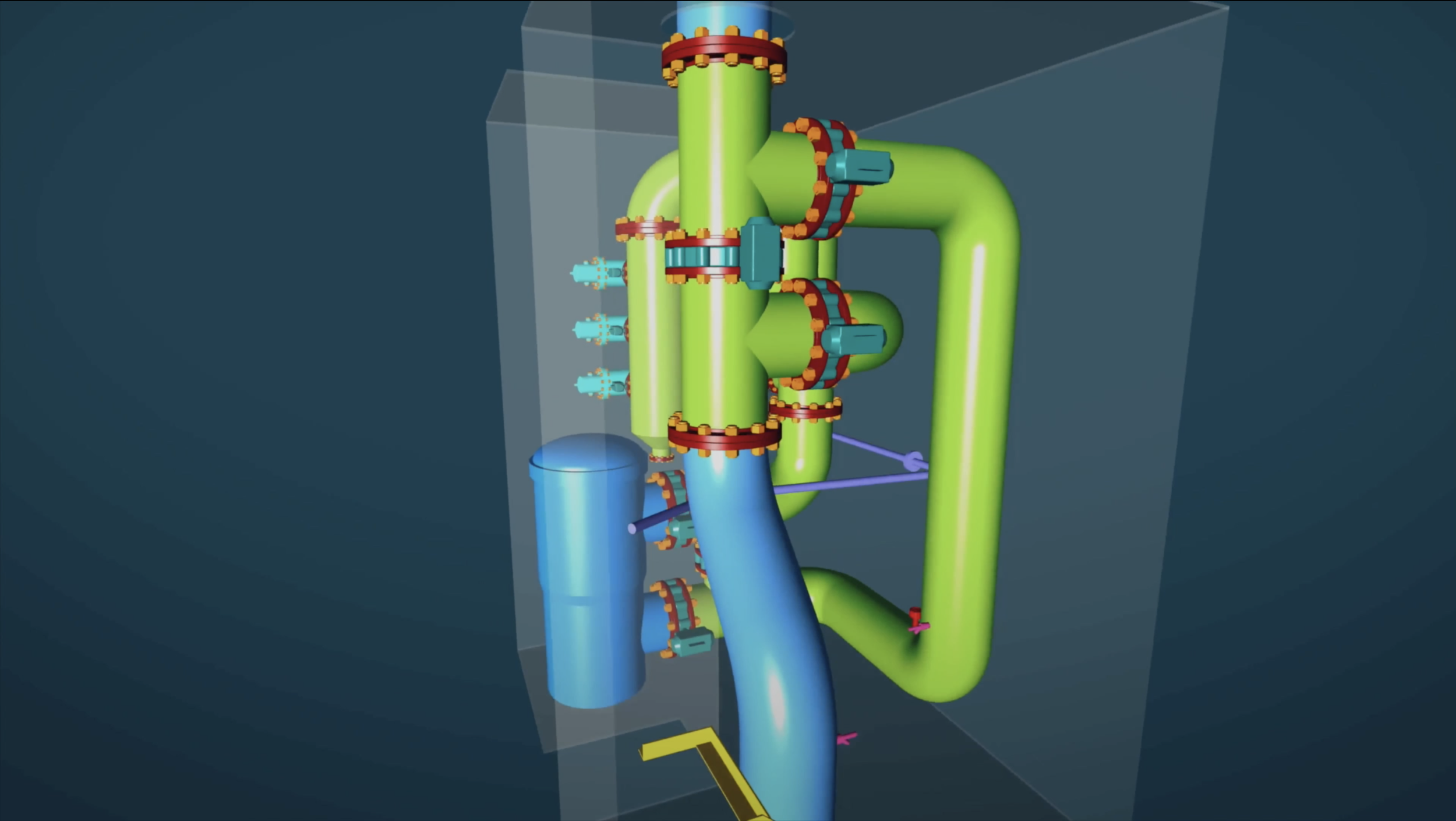

3D CAD Models

Scan to CAD: We offer a range of highly accurate as-built point cloud to 3D CAD model conversions in different formats.

-

BIM Models

Scan to BIM: We offer a variety of as-built point cloud to BIM (Building Information Modeling) model conversions.

-

Plant Design Models

We offer as-built point cloud to plant design model conversion in a variety of plant design model data types.

-

Storage Tank Inspection

Using 3D laser scanning we offer the creation of storage tank inspection reports for both aboveground and underground storage tanks.

-

Volume Surveys

Using 3D scanning we offer highly accurate and fast volumetric surveys often employed in storage tanks, ship ballast and fuel tanks, and stockpiles.

-

2D CAD Documentation

We can create a variety of as-built 2D CAD documentations including but not limited to engineering, architectural, and topographic drawings.

-

Clash Detection

We can compare design model to point cloud or point cloud to point cloud to verify construction as well as perform clash detection analysis.

-

Deformation & Wear Analysis

Using 3D laser scanning and/or CMM measurements we can create 3D color map models for deformation and wear analysis.

-

Topographic Information

Using 3D scan data we can create 2D and 3D topographic information in a variety of formats tailored to your needs.

-

GPR (Underground Mapping)

Using ground penetrating radar (GPR) we offer underground mapping services to produce 2D and 3D data.

-

DIMENSIONAL CONTROL & ALIGNMENT

For applications such as machinery alignment where accuracy is crucial, we offer the use of metrology-grade handheld 3D laser scanners, Faro laser trackers, Faro arms, and Leica total stations.

-

GEOREFERENCING

Using GNSS RTK rovers we offer georeference registered point clouds, BIM models, plant design models, 2D CAD documentation, topographic information, and GPR data.

-

VR/AR & 3D Digital Content

Using 3D laser scanning we are able to convert real-world objects and environments into digital 3D models to be used for applications such as virtual reality (VR), augmented reality (AR), & 3D digital content.

-

XRF & THICKNESS ANALYSIS

Using a XRF analyzer we are able to determine the composition of most elements for reverse engineering. We also employ ultrasonic thickness gauges to accurately measure the thicknesses of objects.

SCAN TO CAD

WHAT IS 3D LASER SCANNING

3D laser scanning is an advanced survey technique that conventional survey techniques cannot match. 3D laser scanning uses a 3D laser scanner to capture millions of unique individual 3D points on the X, Y, and Z-axis. These unique points are captured in a point cloud which maps them in 3D space. This point cloud can be used for numerous applications including the creation of digital twins, 3D mesh models, 3D CAD models, BIM models, plant design models, storage tank inspection, volume surveys, 2D CAD documentation, clash detection, deformation surveys, topographic information, dimensional control & alignment, and wear analysis.

Advantages of 3D Laser Scanning

Accuracy & Efficiency

3D laser scanners can measure up to 2 million points per second with advanced HDR imaging to create colored 3D point clouds with millimeter accuracy.

Safety & Cost

3D laser scanners can measure up to 150 m and emit low-energy light allowing them to be used in hazard-prone areas. The high accuracy of 3D laser scanning also provides economic advantages helping reduce and mitigate errors and setbacks in the planning/design phase as well as in the maintenance of projects.